Description

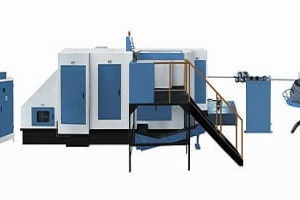

Hydraulic CNC Wire Bending Machine Introduction:

Hydraulic CNC Wire Bending Machine have functions of forming different 2d and 3d shapes on steel wire or stripe.

Metal wire bending machines are mainly used in auto parts industry, concrete construction industry,metal products industry, home hardware industry, such as car seat frame, cage accessories; kitchen and bathroom hardware accessories; garden tool accessories; concrete wire parts,Electrical fittings wire forming, sports equipment fittings wire forming; stationery fittings wireforming, instrument fittings wire forming, instrument fittings wire forming; hair accessories wire forming, handicrafts wire forming, supermarket shelf fittings wire forming, logistics storage accessories wire forming, etc.

Hydraulic CNC Wire Bending Machine Types:

Hydraulic CNC Wire Bending Machine is mainly suitable for wire bending parts from various industries such as hardware, construction, metal wire (sheet) molding, toys, stationery, clothing, lighting, jewelry, electronics and so on. The Hydraulic CNC Wire Bending Machine include: hydraulic buckle bending machine, step-feeding buckle bending machine, PLC control buckle bending machine, luggage buckle bending machine, stationery clip buckle bending machine, headset steel belt bending machine, bucket hook bending machine, crimping machine, double wire heading machine, reeling machine, wire ring bending machine, straightening and cutting machine, hydraulic ring bending machine and other various types of hardware wire (sheet/strip) bending machinery.

Hydraulic CNC Wire Bending Machine Features:

- The automatic 2D 3D wire bending machine adopts Taiwan’s standardized intelligent visual operation control system, which is easy to learn and use. Compared with the traditional PLC system, it is faster and more accurate, and the accuracy can reach 0.05mm.

- The operation panel and touch screen of the automatic 2D 3D wire bending machine are both Chinese and English interfaces, and can be quickly switched, making it easier for beginners to operate and debug the equipment;

- The automatic 2D 3D wire bending machine is equipped with sophisticated sensors and monitoring equipment. In casemechanical failures or unqualified products can automatically stop or issue an alarm;

- The automatic 2D 3D wire bending machine has short material, and can automatically stop and give an alarm when the wire is broken or tangled;

- The automatic 2D 3D wire bending machine is intelligently controlled by the computer system, the machine operation and speed adjustment are simple and convenient, the part forming stability is high, and the speed is fast.

Material suitable to wire forming:

| Material |

Stainless steel,spring steel,low carbon steel |

| Steel wire diameter |

1-12mm for stainless steel,2-10mm for low carbon steel

2-50mm width cs or ss sheet strip |

| Capacity |

10-100pcs per minute as per customer’s product |

| Power |

1.5-11KW |

| Voltage |

380V/50Hz 3p or customized |

| Control mode |

Mechanical control, touch screen control, PLC control,etc. |

Hydraulic CNC Wire Bending Machine Running videos(Youtube platform Playlist):