Description

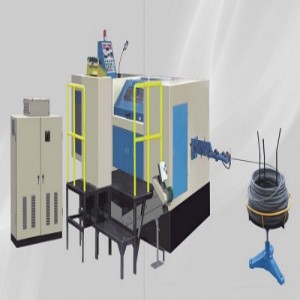

Automatic Four station Cold Bolt Making machine is one kind of specialized machine with high efficiency and automation among forging machinery. Cold forging technique and automatic cold forging machines are used for producing different kinds of bolts, screws, rivets,special parts and nuts in the field of fastener industry. Because of the advantage of the cold forging equipment itself and the superiority of cold forging technique, the cold forging machine also are widely used in different national economic fields for producing fasteners and non-standard parts for industry of aviation steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc.

Items can be produced by the 66S Automatic Special Part Bolt Parts Maker

Flange Bolts, Socket bolts,Hex Bolts, Fastener and Bolts, Hex Cap Screws, Spring Center bolts, Hex Socket Cap Screws, Carriage bolts, solid rivets, square head set screws, truss head track bolts, U Bolts, Fin Neck Bolts, shoulder bolts, coil thread bolts, Structure Liner Bolts, extra long Bolts, Hub Bolts fetter drive screws, wheel bolts, t-head bolts, Flange Bolts, eye bolts, shackle bolts, track bolts, wheel bolts, hex cap screws,auto fasteners,etc.

Main Technical Parameters

| Model | Unit | 66S |

| Forging Station | NO. | 6 |

| Forging force | Tons | 55 |

| Max.cut-off dia. | mm | φ10 |

| Max.cut-off length | mm | 115 |

| Output rate | pcs/min | 90-150 |

| P. K. O. stroke | mm | 25 |

| K.O stroke | mm | 90 |

| Main ram stroke | mm | 160 |

| Main motor power | Kw | 22 |

| Overall dims. Of cut off die | mm | φ50*50L |

| Overall dims. Of punch die | mm | φ45*125L |

| Overall dims. Of main die | mm | φ60*130L |

| Die pitch | mm | 70 |

| Approx. weight | T | 16 |

| Applicable bolt size | mm | 3-8 |

| Shank length of blank | mm | 15-85 |

Annexure I Accessories for 66S Automatic Special Part Bolt Parts Maker

1. One set of trial tools

2. One set of standard hand tools.

3. One set of standard spare parts.

4. One set of Clutch

5. One set of control Panel

6. One set of AC motor

7. transducer speed adjusting system.

8. Full Cover

9. Device of protect revert feed

10. One set of operator stand (The Buyer jointing in the Buyer’s plant)

11. Inside Lamp

12. One set of Safety Device

1. Pneumatic Sensor

2. Oil less Sensor

3. K.O. & P.K.O. Safety pin breakage detector

4. End of material detector

5. Motor Over load detector (including lub., coolant and fan motors)

6. Short Feed detector

7. Air pressure shortage detector

8. Lub. Oil shortage detector

9. Two-hand control unit for jogging

13. Two sets of electrical, operation & maintains manual in English.

14. The following consumables spare of machine drawing will be provided by Seller.

a)Die Locking Screw

b)Punch Locking Screw

c)P.K.O. Lever

d)Punch Bolster for all stations

e)Trimming Cam Drawing

f)K.O. Rod Drawing

g)All safety bolts drawings

h)Ratchet wheel drawing

i)Transfer arm drawing

j)Drawing of straightening rolls

k)Complete set of Electrical drawings

l)Die & Punch Blocks drawings

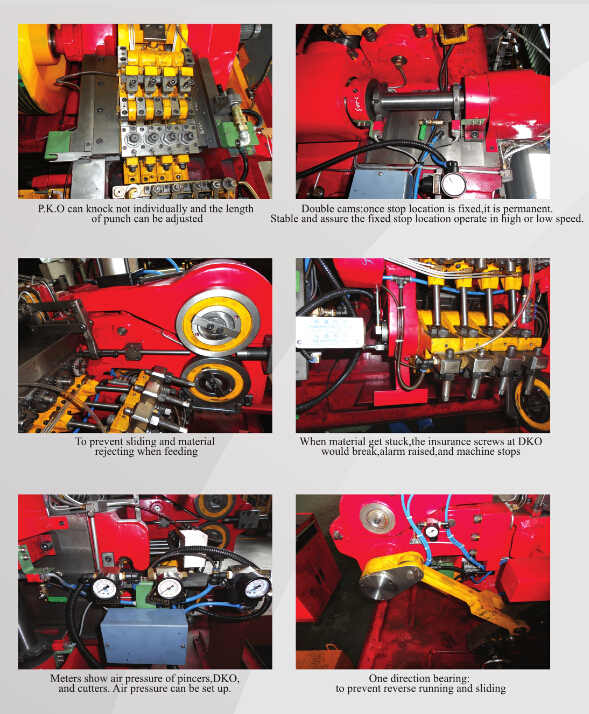

Annexure II Main features for 66S Automatic Special Part Bolt Parts Maker

1. Machine body material: HT300 high quality cast iron by Taiwan investment factory.

2. Main slide material: QT600 ductile iron by Taiwan investment factory.

3. Main crane shaft material 42CrMo forging alloy steel with Nitriding treatment.

4. Main cams, rollers and slide guider plate are made of material SKD-II, with whole body vacuum hardening.

5. Gripping plate is made of aero hard aluminum with hard anodizing treatment.

6. Main die case is made of 42CrMo forging alloy steel.

7. Copper sleeves use phosphor bronze PBC-2

8. The bottom of front and back wing of main slider adopt super wearing inserted copper plate (PBC-2 material) with self lubrication.

9.Air Clutch – Yung Shing, Taiwan

10.PLC – Mitsubishi, Japan

11.All Bearings – NSK & IKO, Japan

12.Inverter – Schneider, France

13.Lubricating Pump – Zhiguan, Taiwan