Description

Salient Features

|

‧

|

STEADY FEEDING OF MATERIAL BY AIR PRESSURE.

|

|

‧

|

EASY ADJUSTMENT AND MAINTENANCE OF BELTS.

|

|

‧

|

RAISES 30% – 40% LIFETIME OF TAP THAN CONVENTIONAL TAP.

|

|

‧

|

HIGHER EFFICIENCY, EASY TO CHANGE TAP AND CAN WORK SEPARATELY BY SINGLE SHAFT.

|

|

‧

|

STOP FEEDING WHEN TAP IS BLUNT OR BAD BORE DIAMETER.

|

|

‧

|

AIR PRESSURE CYLINDER PULLS BACK AUTOMATICALLY TO READY POSITION WHILE DETECTING ABNORMAL OPERATION.

|

|

‧

|

EASY TO CHANGE THE SPEED OF TAPPING BY USING OUR AIR PRESSURE CYLINDER.

|

|

‧

|

ECONOMICALLY SAVE MORE POWER AND LESS SPACE REQUIREMENT.

|

|

‧

|

This machine is designed using the freefall inertia principle and materials inclined closely to one side which will be processed smoothly.

|

|

‧

|

This machine is suitable for the thread tapping process using materials that are super Thin, polygon,irregular,taper profile,etc.

|

|

‧

|

Pneumatic auto-feeding, clamping.and processed releasing are properties of the Multi-functional automated thread tapping sharpener.

|

|

‧

|

Adaptability of comprehensive profile material and easy replacement of tap enhance the muliti function of the machine.

|

|

‧

|

While processing material is rotating,tap and guide tube are stationary;there will be no waste of processing material,no eccentric and precise threading.

|

|

‧

|

The spindle can process materials without stopping which can increase work speed.

|

|

‧

|

For convenient operation, this m/c is installed with counters,failure-indicating lights, etc.

|

|

‧

|

The tapping machine can be used on both iron-based and non-iron-based materials, such as stainless,copper, aluminum, etc.

|

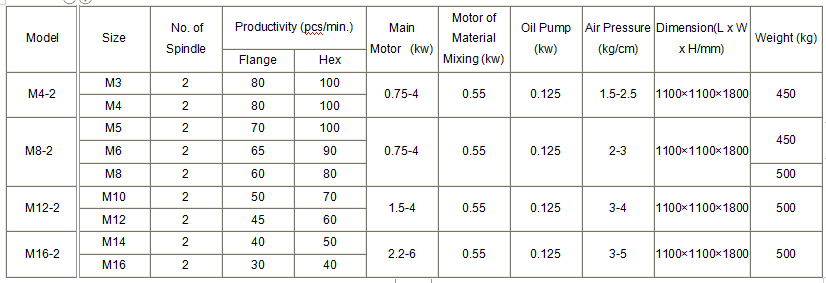

Main Technical Parameters