Description

Simple busbar shearing punching bending machine Specifications

| MODEL | UNIT | AKS-3ST-20 |

|---|---|---|

| PUNCHING MAX. THICKNESS | MM | 12 |

| PUNCHING HOLE DIAMETER | MM | Φ7-Φ21 |

| PUNCHING WIDTH | MM | 30-150 |

| PUNCH OIL CYLINDER FORCE | TON | 20(630KN) |

| SHEARING MAX. THICKNESS | MM | 10 |

| SHEARING WIDTH | MM | 30-150 |

| HONRIZENTAL BENDING FORCE | TON | 15 |

| HONRIZENTAL BENDING THICKNESS | MM | 12 |

| HONRIZENTAL BENDING WIDTH | MM | 150*10 |

| VERTICAL BENDING MAX. WIDTH | MM | 120*10 |

| SUIT MATERIAL | COPPER BARS AND ALUMINIUM BARS | |

| WEIGHT | TON | 0.17 |

Simple busbar shearing punching bending machine Applications and Features

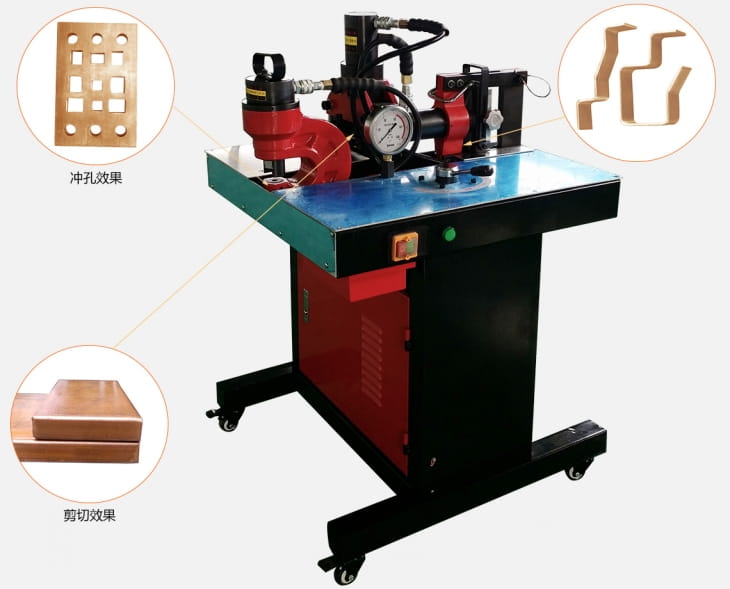

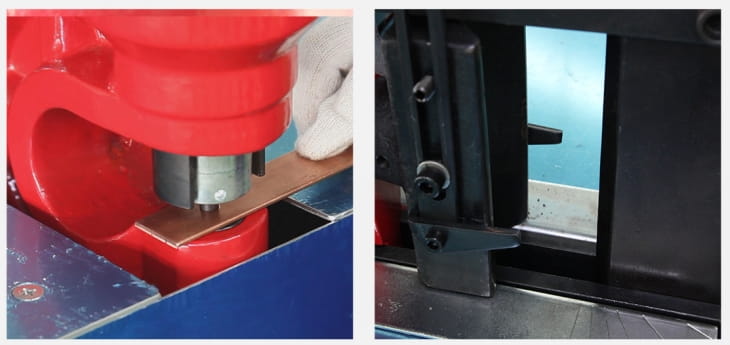

Application:Simple power bus processing machine is mainly used in switchgear and transformer manufacturing industries. It is used to process various specifications of copper and aluminum busbars. It is suitable for on-site construction in workshops and power transmission and distribution work, and electrical appliances such as power distribution cabinets and switch cabinets Used by the manufacturer. This machine has the functions of cutting, punching and flat bending.

Features:

1.Small size, high flexibility and easy to carry. It is flexible and convenient to move, which is beneficial to the power site processing.

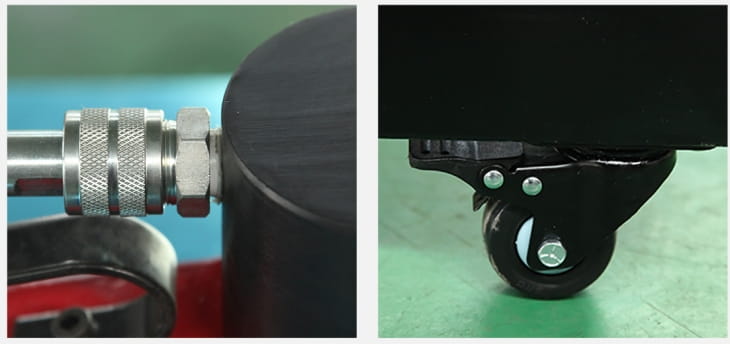

2.The machine is simple design, flexible and convenient to operate. By replacing the quick-change joints, the three units of busbar cutting punching and bending can be switched between each other.

3.The machine is equipped with universal wheels for easy movement.

Simple busbar shearing punching bending machine Structure and Components

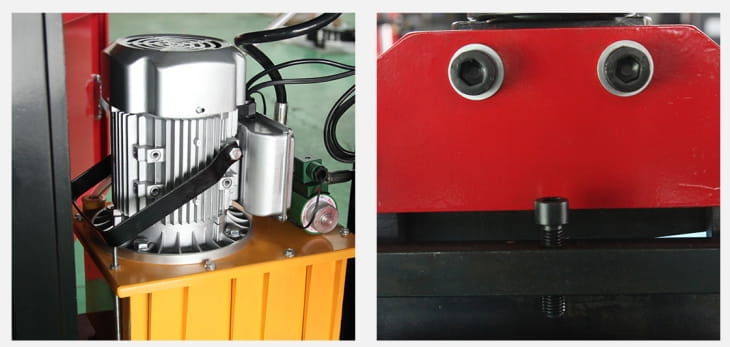

High performance hydraulic motor station Good positioning shear cutting unit

Nested mold punching unit High precision shape forming unit

Highly sealed hydraulic oil pipeline Universal wheels for easy movement

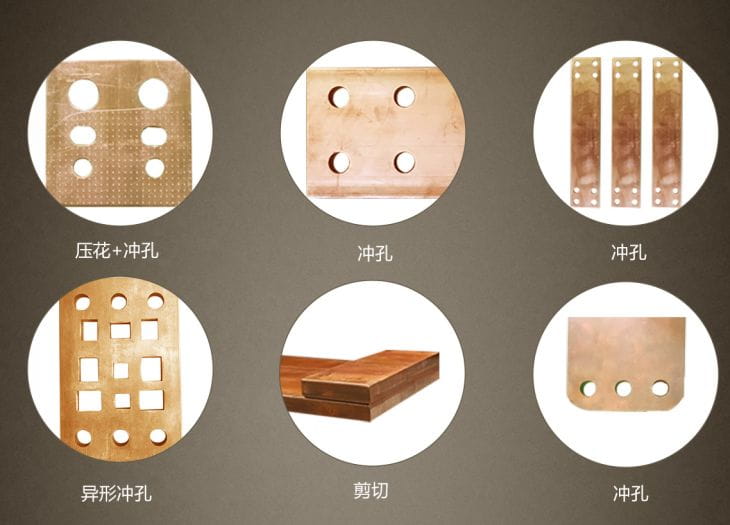

Simple busbar shearing punching bending machine Produced Busbar Samples

Bus bar various shapes and samples

1.Sheared bus bar plate 2.Standing bend and twisted bus bar 3.Holes punched bus bar 4.U shape bending bus bar 5.Holes punched and knurling pressed bus bar 6.8.Punch and bend combination bus bar 7.Twisted bus bar