Description

Main features of Four stations bolt forging machine:

1. The machine body, main slider, and the punch connecting rod adopt QT500~QT550 ductile iron. Taiwan invests in well-known brands and adopts the reverse casting process. Although the cost is 1~1.5 yuan/KG higher than other manufacturers, but it is the basis of a good machine. (Tensile resistance and high impact resistance. Generally, the other manufacturers use HT gray iron or low-cost ball milled cast iron.

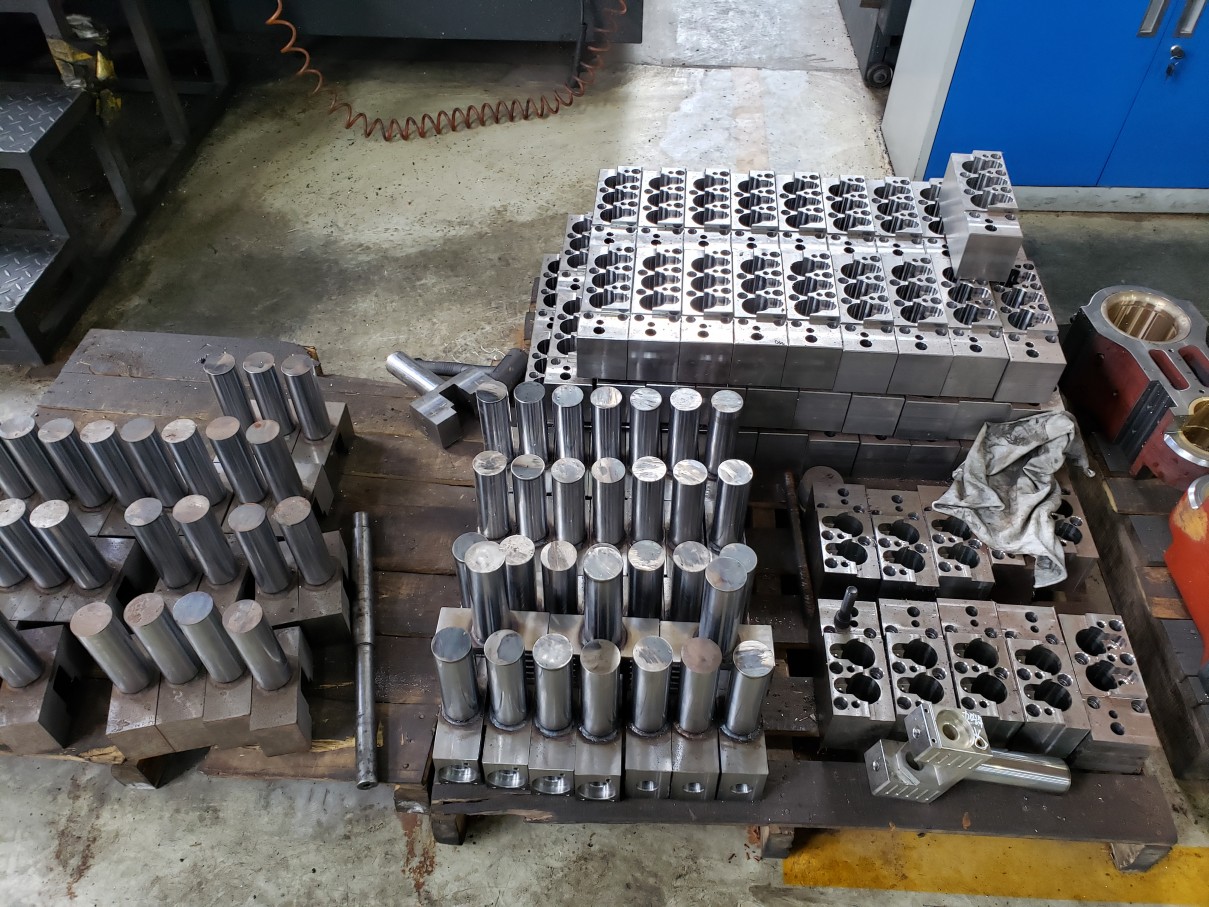

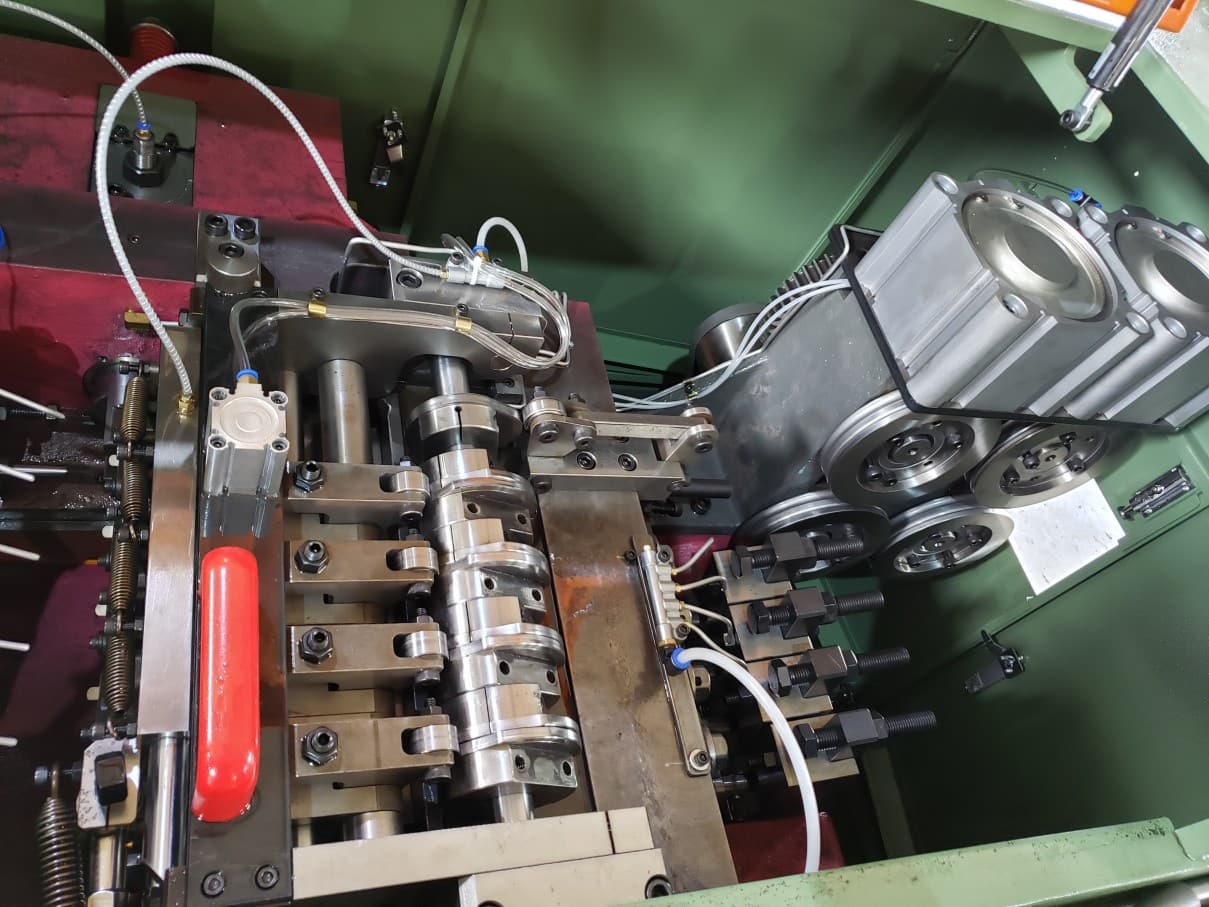

2.The crankshaft, die box seat, punch die seat, double cam, punch connecting rod and large pin shaft are made of 38COMOAT material and nitriding treatment. The surface hardness can reach HV850~950, which has excellent stability and longevity (generally manufacturers use 42COMO High-frequency quenching treatment, although it is ok to use, it is slightly inferior in terms of resistance to seizure, deformation, abrasion, and breakage).

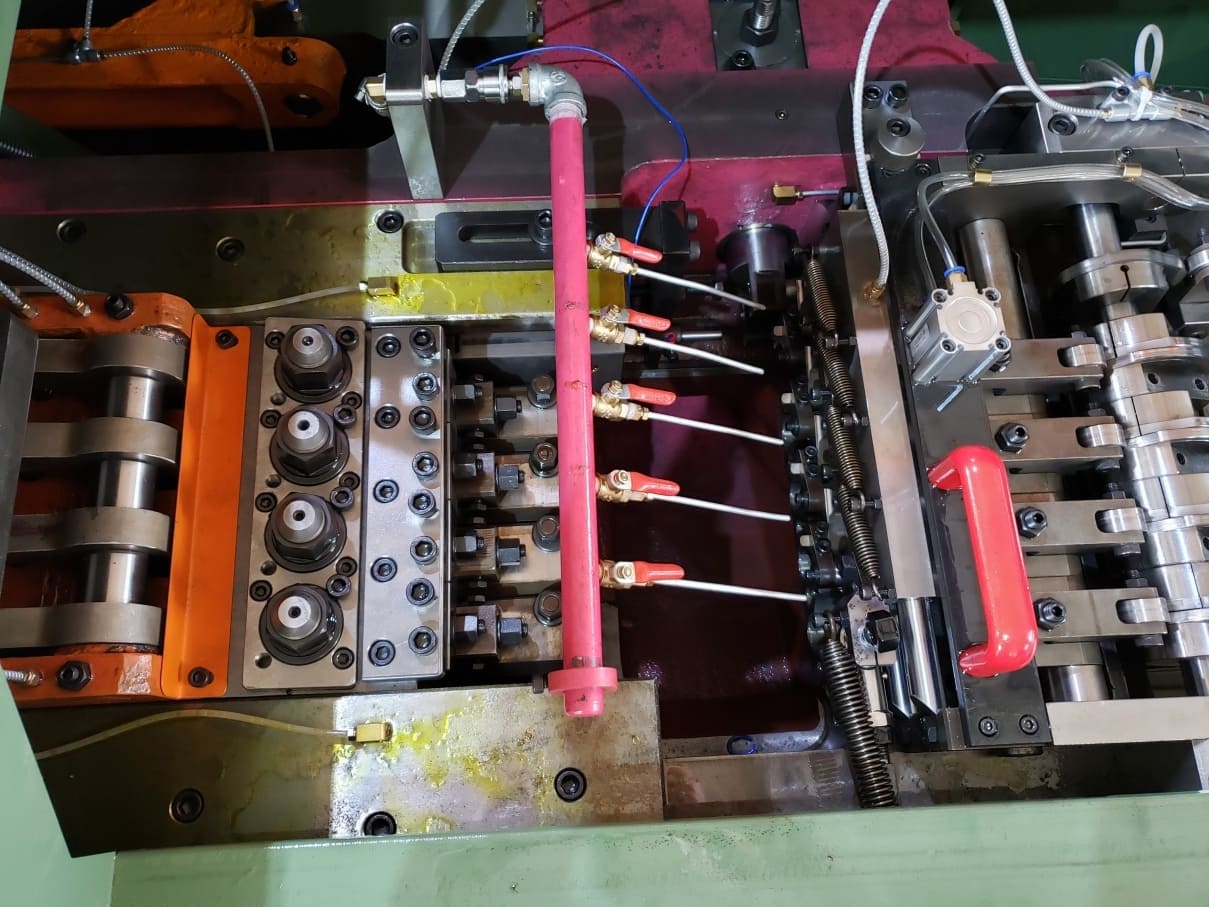

3. The guide plate is made of wear-resistant alloy steel with full quenching treatment, which has good anti-seize and abrasion resistance. If it is overhauled after more than ten years, it will only be flat polishing little bit then will like a new one. (Generally manufacturers use surface quenching which only the surface is hard, and the hardness drops too much after grinding, and it is difficult to use for a long time.) The cylinder-type clamp frame assembly also uses a nitriding process to maintain high stability and long life (although it is heavier than aluminum clamp frame Some but significantly longer lifespan).

4.The copper tile and copper sleeve of the whole machine are made of PBC-2 (10-1) tin phosphor bronze, which has good wear resistance. Some models with a separate clamp seat use P-20 aviation aluminum which is surface-hardened, which overcomes the shortcomings of aluminum soft and short life.

5.The spring adopts Japanese and Korean brands, the important parts of the bearing adopts NSK and IKO brands, and the screw adopts TUZ brand 12.9 grade, which has high strength.

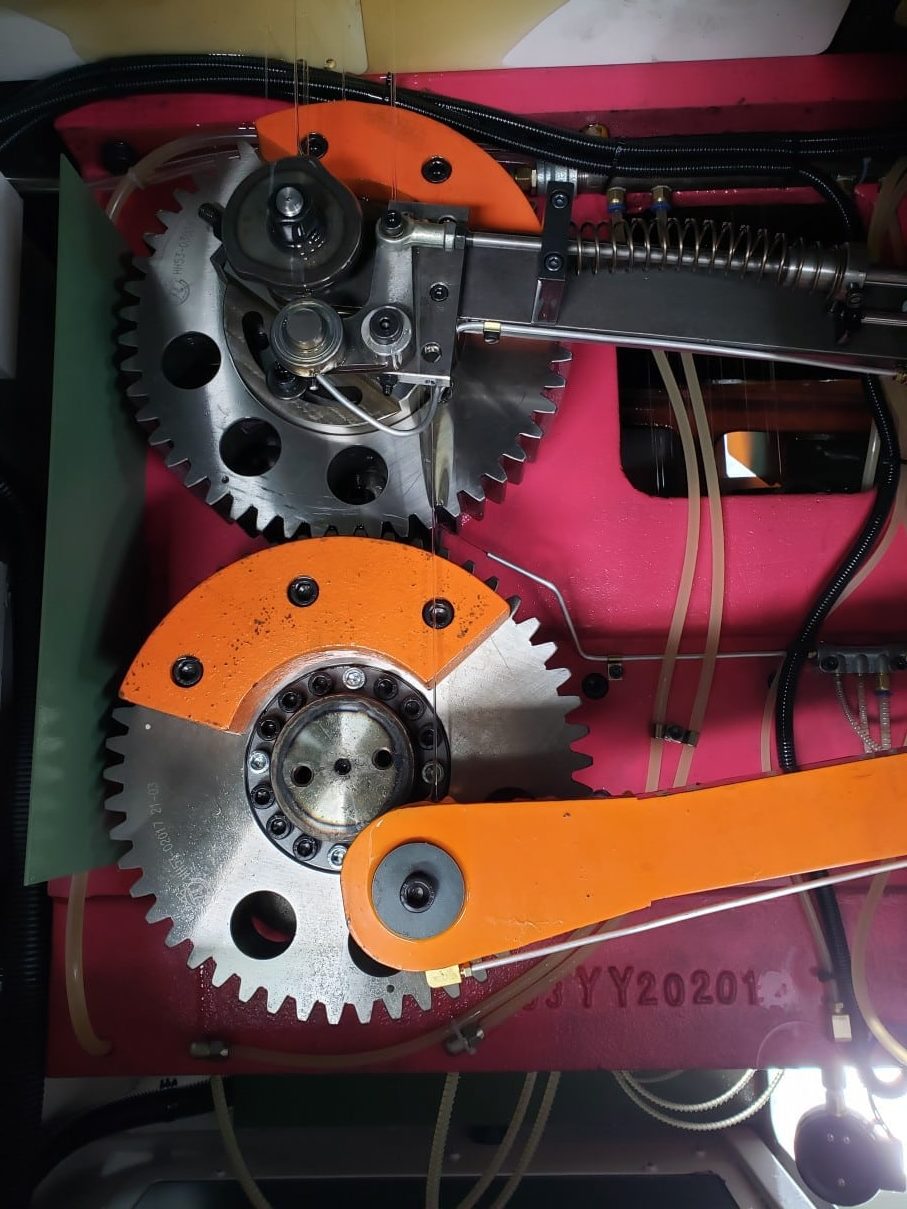

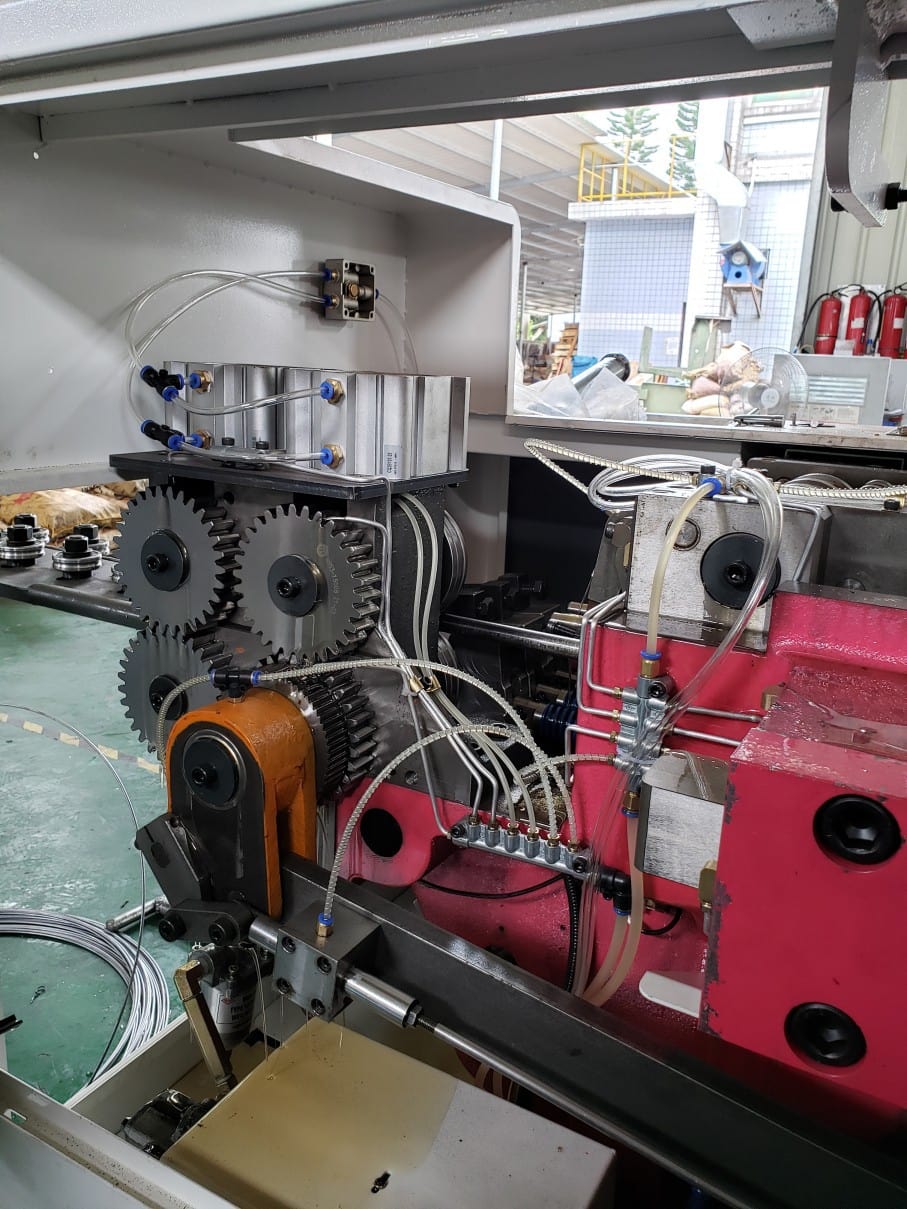

6.The gears are all processed by high-frequency quenching first,then grinding the teeth to ensure the accuracy and low noise of the machine. At the same time, the transmission efficiency is high and the life is long.(It is also ok to use if it is not quenched and finely grinded, so the general manufacturer does not do this).

7.Pneumatic components adopt Japanese SMC and less Taiwanese Airtac brands, with fewer failures and long service life.

8.Both ends of the crankshaft of M16 and above large machine, the connecting rod Huff big copper sleeve, and the back shaft both ends copper sleeve are equipped with five copper sleeve temperature monitoring instruments as standard, which can monitor the copper sleeve at any time due to lack of oil, deformation or poor tubing. If the temperature rises above 50℃, it will alarm and stop, which can effectively prevent the expansion of the fault and prolong the life of the machine.

9.The remote monitoring function (optional) is convenient for production management and statistical work. It can monitor the startup, shutdown time, speed, number of good products, etc. at any time, and even directly shut down the machine. If there is a preheating requirement in winter, the machine can be pre-heated remotely.

10.Micro-moving machine adjusting system; in the process of adjusting the machine, there are high requirements for the center of the clamp, the center of the punch hole and the main mold hole, and the material and mold. This system can avoid the fatigue of the operator’s hand pulling the flywheel and inching the main slider over to cause clamps and molds are damaged. (The jog hand wheel and servo main motor are also optional).

11.Raw wire material feeding, drive motor make feeding easily and save time.

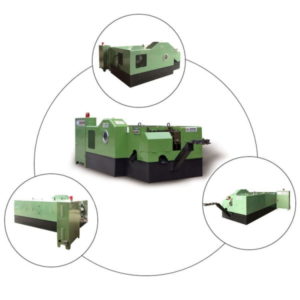

Main technical parameters of Four stations bolt forging machine:

| Four Stations Multi Stage High Speed Bolt Making Machine | |||||||

| Model | Unit | 44S | 64S | 84S | 104S | 104L | 134L |

| Forging Station | NO. | 4 | 4 | 4 | 4 | 4 | 4 |

| Forging force | Tons | 16 | 35 | 60 | 80 | 80 | 120 |

| Max.cut-off dia. | mm | Φ4 | φ8 | φ10 | φ12 | φ12 | φ15 |

| Max.cut-off length | mm | 66 | 80 | 115 | 135 | 185 | 190 |

| Output rate | pcs/min | 350 | 140-210 | 120-180 | 90-140 | 80-130 | 75-110 |

| P. K. O. stroke | mm | 12 | 12 | 18 | 20 | 30 | 40 |

| K.O stroke | mm | 52 | 70 | 92 | 118 | 160 | 175 |

| Main ram stroke | mm | 95 | 110 | 160 | 190 | 262 | 270 |

| Main motor power | Kw | 11 | 15 | 22 | 30 | 30 | 37 |

| Overall dims. Of cut off die | mm | Φ20 | φ30*45L | φ50*50L | φ45*59L | φ45*59L | φ63*69L |

| Overall dims. Of punch die | mm | Φ35*75L | φ40*90L | φ45*125L | φ53*115L | φ53*115L | φ60*130L |

| Overall dims. Of main die | mm | Φ40*85L | φ50*85L | φ60*130L | φ75*135L | φ75*185L | φ86*190L |

| Die pitch | mm | 50 | 60 | 70 | 90 | 94 | 110 |

| Approx. weight | T | 4.3 | 8 | 14 | 18 | 21 | 28 |

| Applicable bolt size | mm | 1-4 | 3-6 | 5-8 | 6-10 | 6-10 | 8-12.7 |

| Shank length of blank | mm | 6-50 | 10-65 | 15-90 | 15-110 | 20-152 | 20-160 |

| Model | Unit | 134LL | 134LLL | 164S | 164LL | 204L | 204LL |

| Forging Station | NO. | 4 | 4 | 4 | 4 | 4 | 4 |

| Forging force | Tons | 120 | 120 | 210 | 210 | 350 | 350 |

| Max.cut-off dia. | mm | φ15 | φ15 | φ18 | φ18 | Φ23 | Φ23 |

| Max.cut-off length | mm | 265 | 285 | 195 | 350 | 240 | 360 |

| Output rate | pcs/min | 50-80 | 50-80 | 70-100 | 70-100 | 55-80 | 60 |

| P. K. O. stroke | mm | 40 | 40 | 40 | 45 | 46 | 45 |

| K.O stroke | mm | 225 | 280 | 178 | 330 | 220 | 330 |

| Main ram stroke | mm | 380 | 380 | 260 | 346 | ||

| Main motor power | Kw | 37 | 37 | 55 | 55 | 75 | 75 |

| Overall dims. Of cut off die | mm | φ63*69L | φ63*69L | Φ60*90L | Φ60 | Φ75*120L | Φ75 |

| Overall dims. Of punch die | mm | φ60*229L | φ60*229L | Φ75*185L | Φ75*185L | Φ90*215L | Φ90*190L |

| Overall dims. Of main die | mm | φ86*305L | φ86*305L | Φ100*190L | Φ100*345L | Φ125*240L | Φ125*345L |

| Die pitch | mm | 110 | 110 | 120 | 126 | 140 | 138 |

| Approx. weight | T | 33 | 38 | 45 | 66 | 62 | 75 |

| Applicable bolt size | mm | 8-12.7 | 8-12.7 | 10-16 | 10-16 | 12-20 | 12-20 |

| Shank length of blank | mm | 40-220 | 75-262 | 20-160 | 100-300 | 25-200 | 100-300 |

| Model | Unit | 254S | 254L | 304L | 364L |

| Forging Station | NO. | 4 | 4 | 4 | 4 |

| Forging force | Tons | 430 | 430 | 550 | 750 |

| Max.cut-off dia. | mm | Φ28 | Φ29 | Φ38 | Φ42 |

| Max.cut-off length | mm | 253 | 320 | 450 | 450 |

| Output rate | pcs/min | 40-70 | 60 | 45 | 45 |

| P. K. O. stroke | mm | 40 | 60 | 80 | 80 |

| K.O stroke | mm | 205 | 290 | 400 | 400 |

| Main ram stroke | mm | 330 | |||

| Main motor power | Kw | 90 | 90 | 132 | 200 |

| Overall dims. Of cut off die | mm | Φ80*130L | Φ90 | Φ115 | Φ145 |

| Overall dims. Of punch die | mm | Φ120*270L | Φ105*232L | Φ135*240L | Φ155*265L |

| Overall dims. Of main die | mm | Φ140*250L | Φ160*294L | Φ185*420L | Φ195*420L |

| Die pitch | mm | 160 | 174 | 200 | 220 |

| Approx. weight | T | 105 | 105 | 186 | 258 |

| Applicable bolt size | mm | 14-25.4 | 16-25.4 | 20-33 | 30-38 |

| Shank length of blank | mm | 35-200 | 35-250 | 80-350 | 80-350 |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

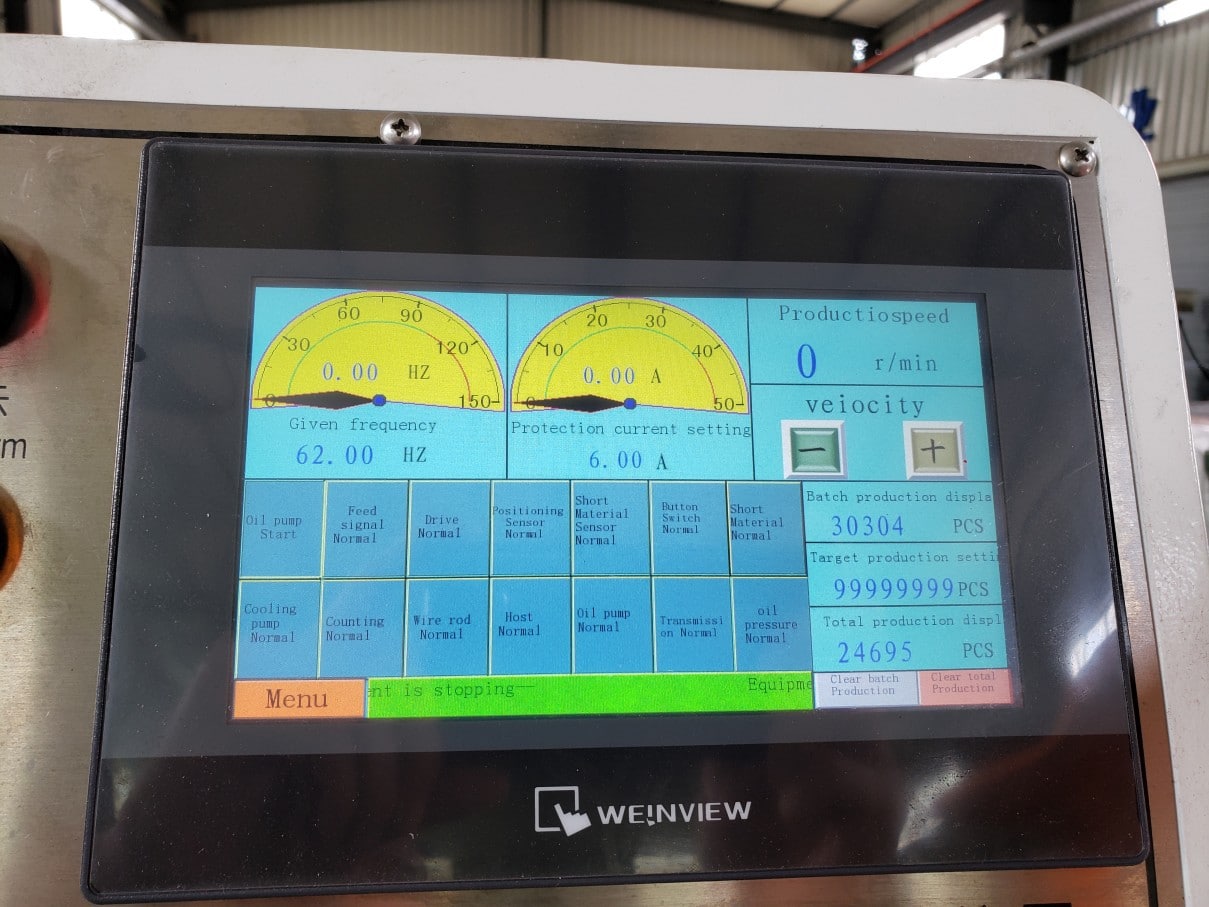

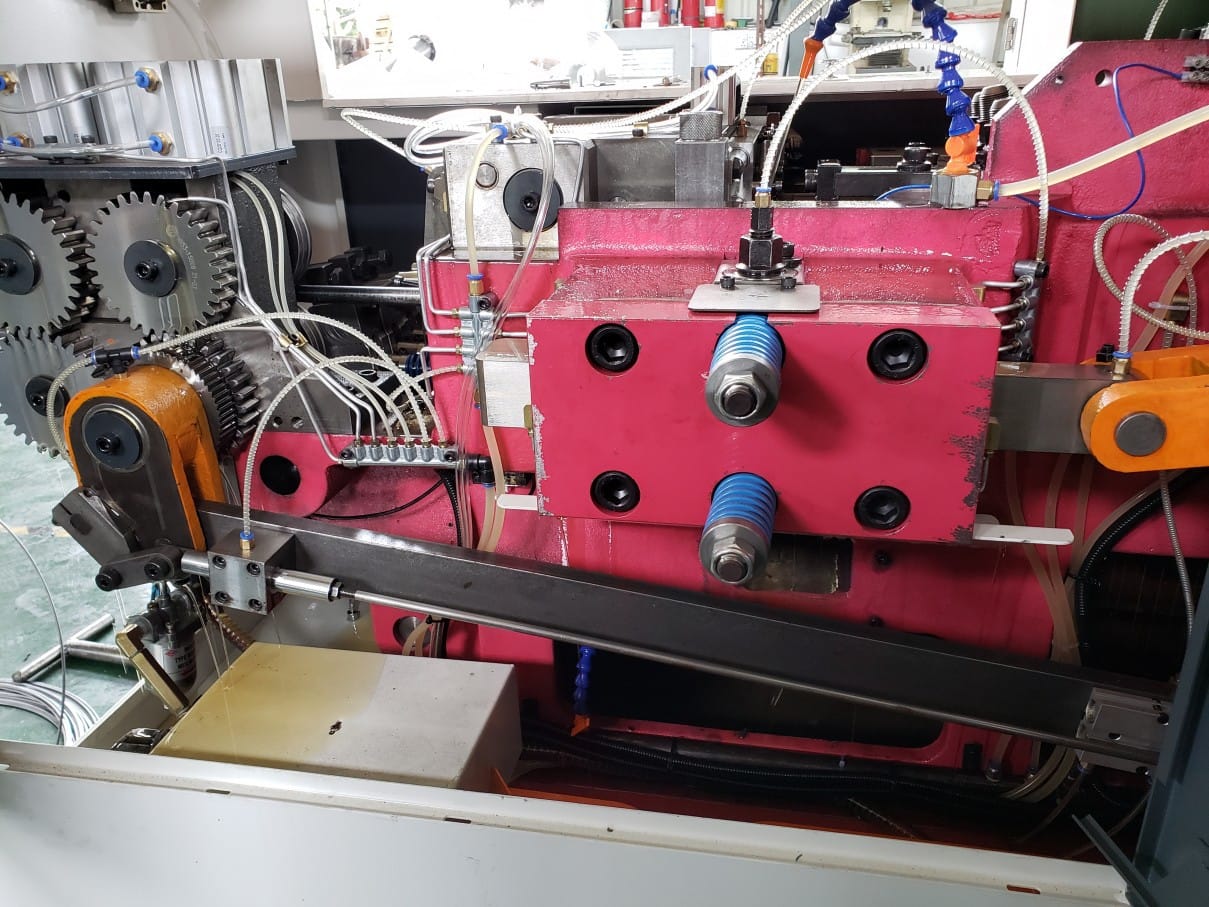

Details show of four stations bolt forging machine:

|

|

|

|

|

|

|

|

Four stations bolt forging machine running videos:

| stainless 430 deep hole rivet cold forging machine | three stations screw bolt rivet making machine |