Description

Main features of three stations bolt forging machine:

1.Cast iron is made of alloy cast iron with excellent tensile strength, and has been inspected by professional third party. It has excellent shock absorption performance. In the case of high-speed stamping and high-speed feeding, the body Is stableand the vibration Is small which ensures the long-term accuracy of the machine.

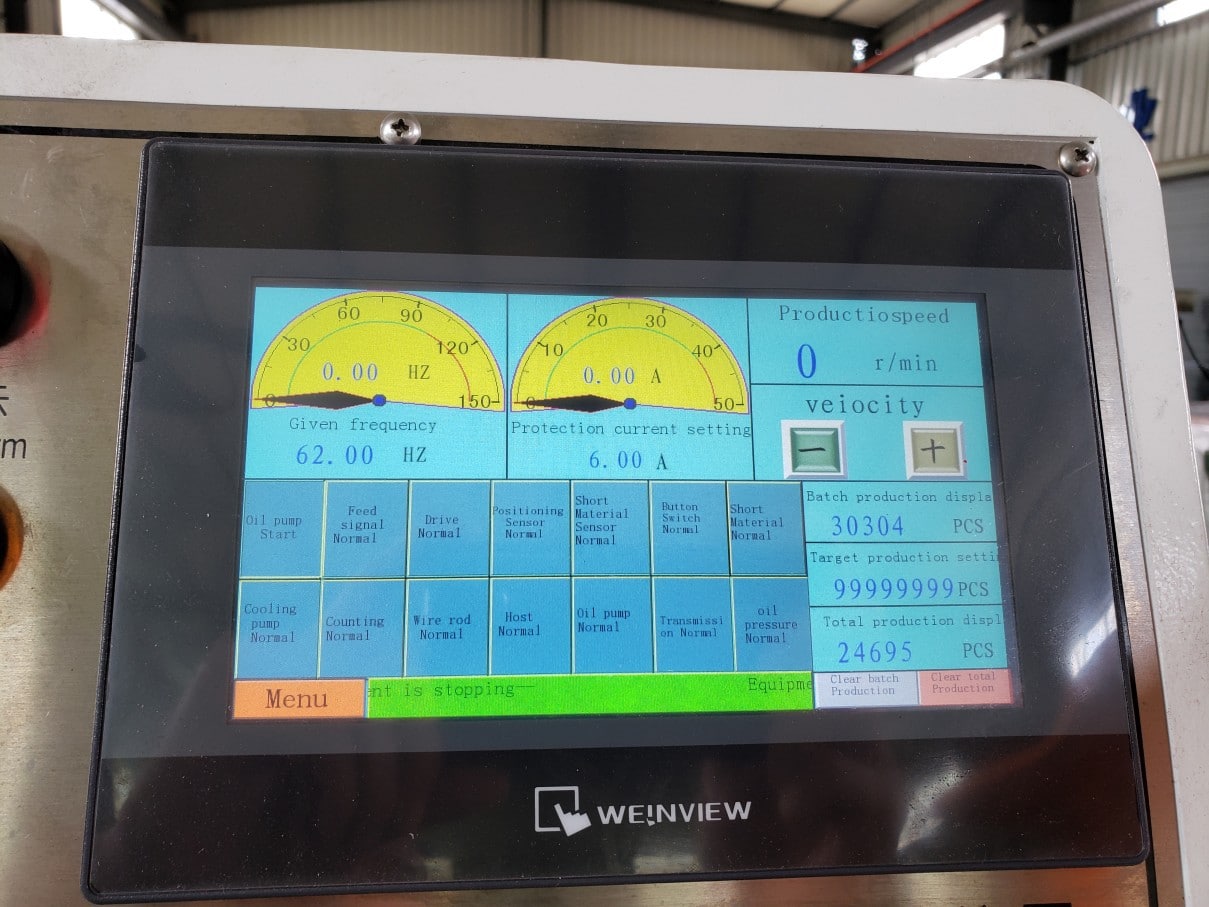

2.Dynamic balance system is adopted to ensure stable and accurate high-speed operation.

3.The servo motor PLC electric control system is adopted to realize the detection of oil pressure, air pressure, voltage, current and other machine operation conditions.

4.Self developed humanized operation interface, emphasizing the safety and convenience of operators.

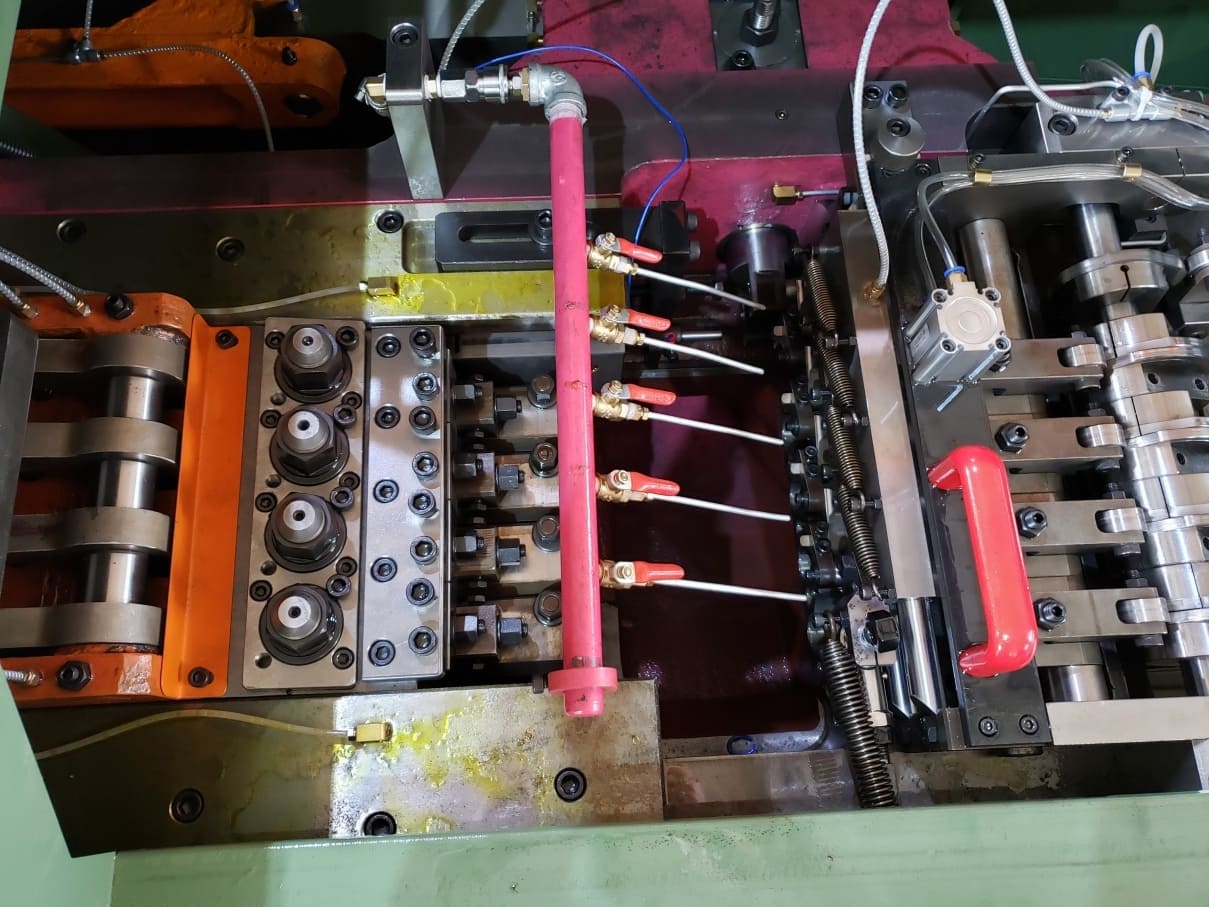

4.The cutting system developed by our own patent can realize the quick installation of the cutter, optimize the cutting curve and ensure the smooth and stable cutting.

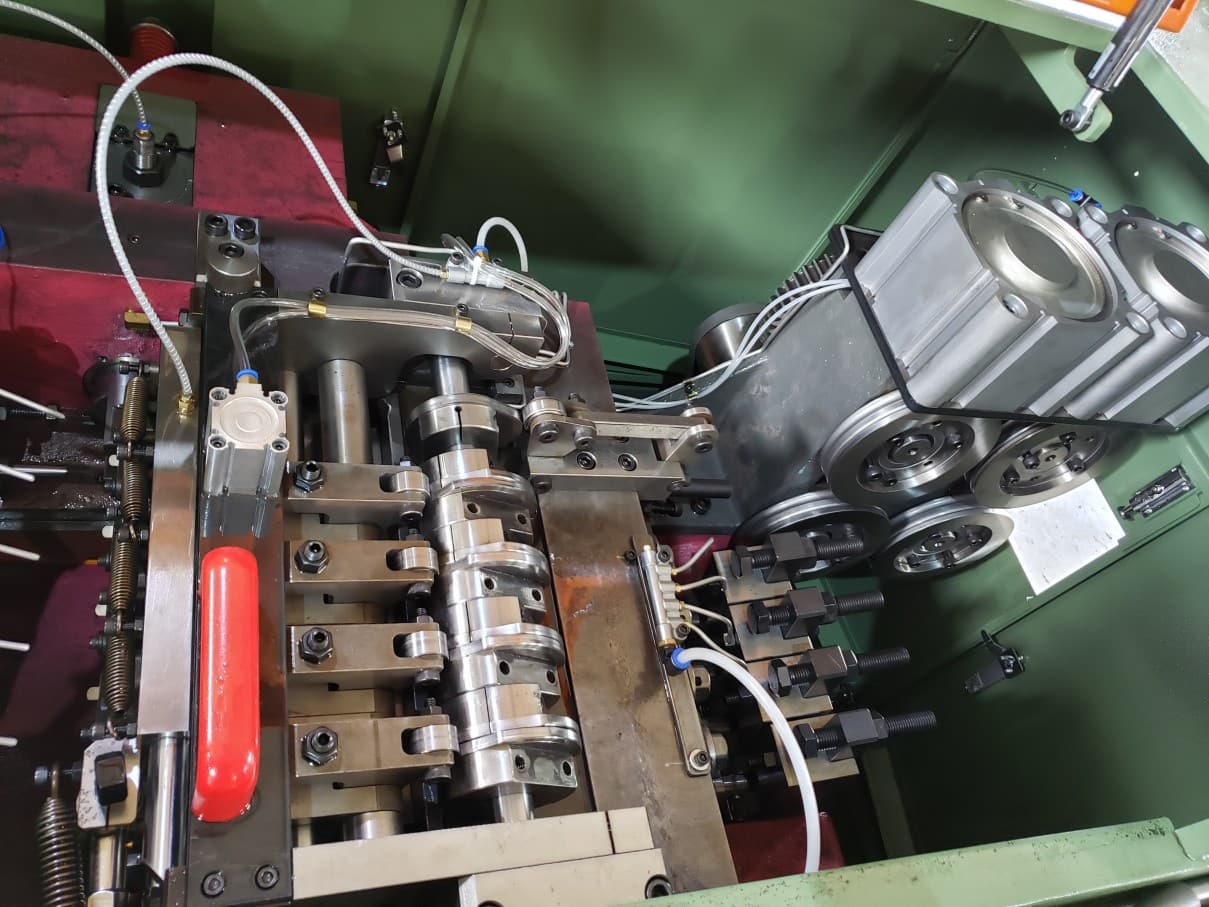

5.The modular clamp system developed by our own patent has the advantages of high speed and precision,convenient operation and easy maintenance. It can save the time for the operator to adjust the machine and reduce the learning time of the fresh operator.

6.The machine adopts enlarged crankshaft and connecting rod to enhance the impact resistance and reduce the elastic deformation. The machine has high hardness and excellent wear resistance with large area contact. It is not easy to occur shaft holding phenomenon. It can adapt to high-grade alloy copper sleeve and bearing bush with high load and high sliding speed(8m/s). The wear resistance and front dead center of the machine are guaranteed for a long time.

7.The machine gear adopts whole heat treatment and high precision gear teeth grinding technology to ensure long-term wear resistance and low noise.

Main technical parameters of three stations bolt forging machine:

| THREE STATIONS HIGH SPEED BOLT MAKING MACHINE | |||||||

| MODEL | UNIT | 43S | 63S | 63L | 83S | 83L | 83LL |

| FORGING STATION | NO. | 3 | 3 | 3 | 3 | 3 | 3 |

| FORGING FORCE | TONS | 16 | 35 | 35 | 60 | 60 | 65 |

| MAX.CUT-OFF DIA. | MM | 4 | 8 | 8 | 10 | 10 | 10 |

| MAX.CUT-OFF LENGTH | MM | 66 | 70 | 120 | 85 | 135 | 175 |

| OUTPUT RATE | PCS/MIN | 350 | 270 | 150 | 220 | 160 | 120 |

| P. K. O. STROKE | MM | 12 | 12 | 20 | 12 | 15 | 30 |

| K.O STROKE | MM | 52 | 52 | 115 | 65 | 125 | 165 |

| MAIN MOTOR POWER | KW | 11 | 11 | 11 | 15 | 22 | 22 |

| OVERALL DIMS. OF CUT OFF DIE | MM | Φ20 | Φ30 | Φ30 | Φ30 | Φ30 | Φ30 |

| OVERALL DIMS. OF PUNCH DIE | MM | Φ35*75L | Φ40*90L | Φ40*110L | Φ45*100L | Φ45*115L | Φ45*115L |

| OVERALL DIMS. OF MAIN DIE | MM | Φ40*85L | Φ50*85L | Φ50*123L | Φ60*95L | Φ60*135L | Φ60*185L |

| DIE PITCH | MM | 50 | 60 | 60 | 70 | 80 | 80 |

| APPROX. WEIGHT | T | 4 | 7 | 9 | 10 | 13 | 15.5 |

| APPLICABLE BOLT SIZE | MM | 1-4 | 3-6 | 3-6 | 5-8 | 5-8 | 5-8 |

| SHANK LENGTH BELOW HEAD | MM | 6-50 | 10-50 | 30-100 | 12-60 | 30-110 | 30-110 |

| MODEL | UNIT | 103S | 103L | 133S | 133L | 133LL | 163S | 203L |

| FORGING STATION | NO. | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| FORGING FORCE | TONS | 80 | 90 | 105 | 120 | 130 | 190 | 350 |

| MAX.CUT-OFF DIA. | MM | 12 | 12 | 15 | 15 | 15 | 18 | 23 |

| MAX.CUT-OFF LENGTH | MM | 105 | 190 | 140 | 250 | 350 | 195 | 250 |

| OUTPUT RATE | PCS/MIN | 180 | 130 | 150 | 100 | 70 | 100 | 75 |

| P. K. O. STROKE | MM | 15 | 30 | 20 | 30 | 60 | 30 | 45 |

| K.O STROKE | MM | 80 | 165 | 110 | 220 | 330 | 170 | 220 |

| MAIN MOTOR POWER | KW | 22 | 22 | 30 | 37 | 37 | 45 | 75 |

| OVERALL DIMS. OF CUT OFF DIE | MM | Φ45 | Φ45 | Φ55 | Φ55 | Φ55 | Φ60 | Φ75 |

| OVERALL DIMS. OF PUNCH DIE | MM | Φ53*115L | Φ53*115L | Φ60*115L | Φ60*170L | Φ60*250L | Φ75*185L | Φ90*190L |

| OVERALL DIMS. OF MAIN DIE | MM | Φ75*108L | Φ75*185L | Φ85*135L | Φ85*265L | Φ90*340L | Φ100*190L | Φ125*240L |

| DIE PITCH | MM | 90 | 90 | 110 | 110 | 110 | 126 | 138 |

| APPROX. WEIGHT | T | 13.8 | 19 | 18 | 25 | 36 | 38 | 58 |

| APPLICABLE BOLT SIZE | MM | 6-10 | 6-10 | 8-12.7 | 8-12.7 | 8-12.7 | 10-16 | 12-20 |

| SHANK LENGTH BELOW HEAD | MM | 15-75 | 30-150 | 20-105 | 50-205 | 100-300 | 20-155 | 25-200 |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

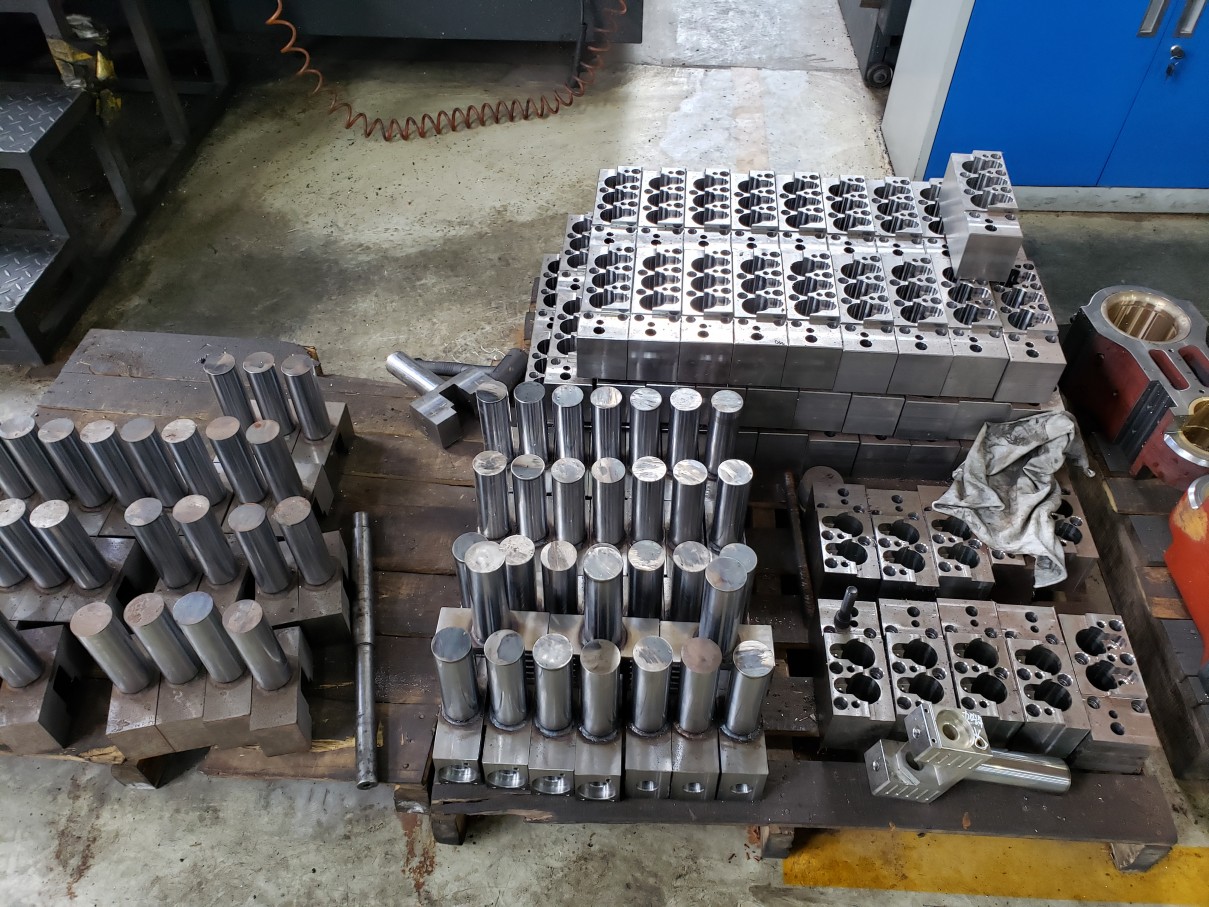

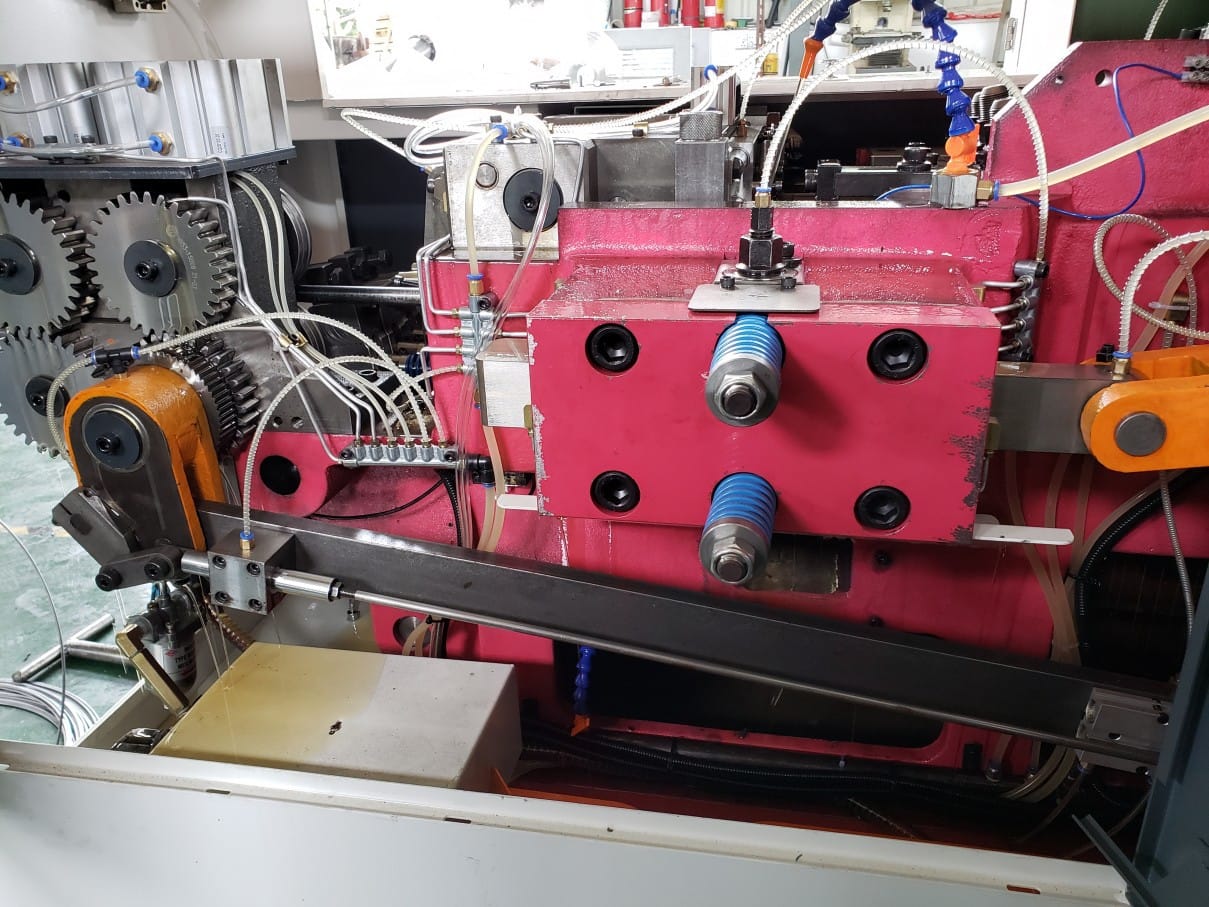

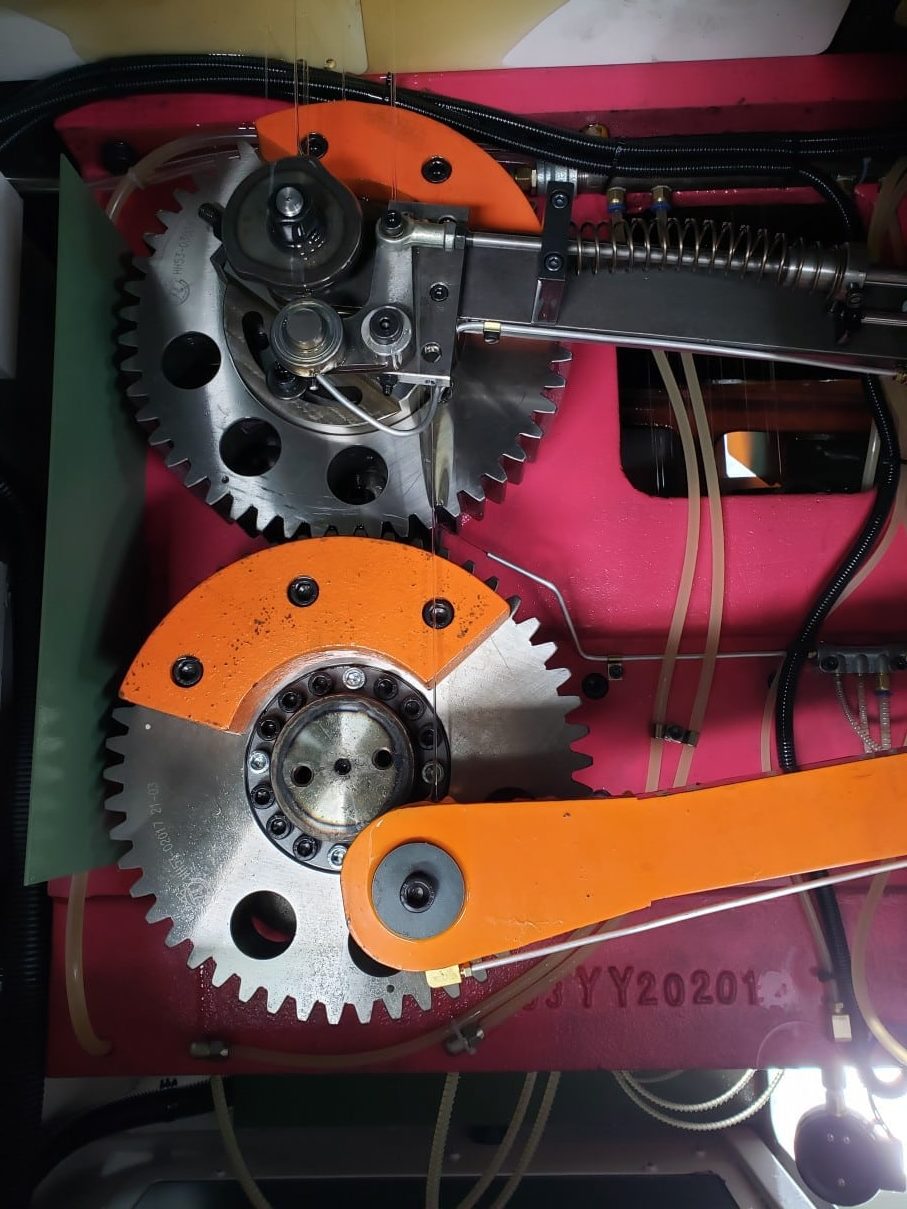

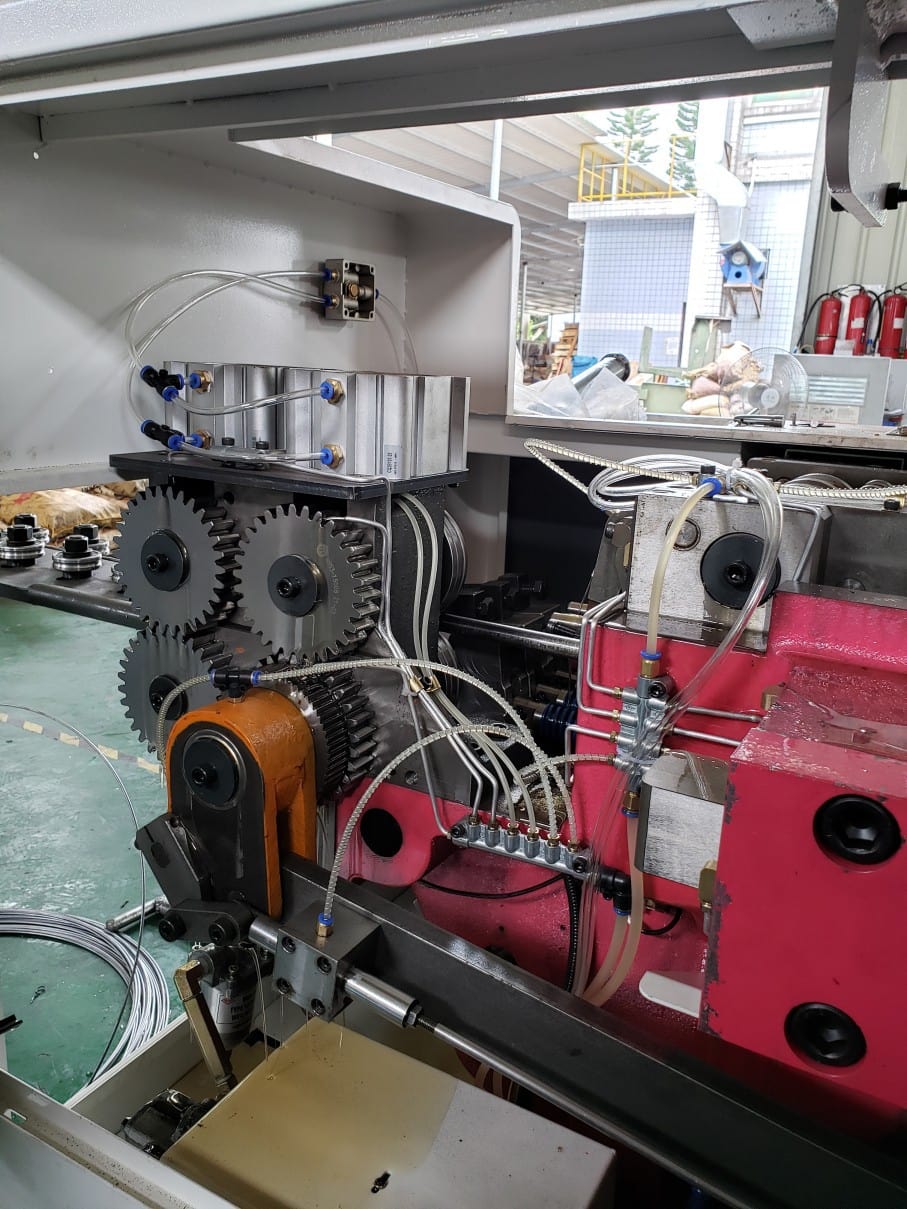

Details show of three stations bolt forging machine:

|

|

|

|

|

|

|

|

Three stations bolt forging machine running videos:

| stainless 430 deep hole rivet cold forging machine | three stations screw bolt rivet making machine |